By: Aaron Schulman

Knowing the major brands of acoustic guitars does not guarantee that in buying one of those brands you will get a superior instrument. Even popular brands of guitars are sometimes poor in quality. The trick isn’t to know the top selling brands, rather, it’s to know what goes into quality craftsmanship of a fine acoustic.

Knowing the major brands of acoustic guitars does not guarantee that in buying one of those brands you will get a superior instrument. Even popular brands of guitars are sometimes poor in quality. The trick isn’t to know the top selling brands, rather, it’s to know what goes into quality craftsmanship of a fine acoustic.

Whether you are jamming on the Taylor 110 series or a less-known model, it helps to know your woods. In knowing the best types of tonewoods, their functions, and what skill needs to be added into making the guitar neck, soundboard, back, and sides, you will be able to make a wise investment into an instrument that will last you many years. This article is designed to help you understand the artistry and workmanship that must go in to creating an excellent neck and fretboard of an acoustic guitar.

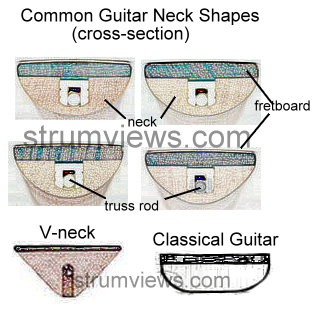

As mentioned in previous articles, there are two basic types of acoustic guitars – classical and steel string. The neck of a classic acoustic will be wide and flat, whereas a steel string acoustic will be narrower. The radius of the neck of a classical will seem flat compared to more curved steel string.

The strings and blocks along the neck of a guitar are known as frets. The fretboard, or fingerboard, as it is also known, will provide nearly endless musical arrangements, despite having what appears to be a simple layout. A fretboard is always divided mathematically into frets to keep the intonation of the guitar correct. These progressive divisions will be the same (to scale) no matter the size of the guitar. However, the length of the fretboard will change depending on the size of the guitar (thereby changing the fret size). A smaller acoustic guitar will have a shorter fretboard, but will have the same gradual fret divisions as other guitars of varying sizes. Likewise, there are a few popular neck scale lengths with varying fret numbers, depending on the model of the guitar and where the neck is attached to the body of the guitar.

Fret bars are made with fret wire. Fret wire should be heavy-duty, yet smooth and polished. This makes playing relaxed and easy. It should also have low internal damping. This keeps the string vibration and resonance consistent and lowers the loss of sound and vibrations. Some common fret wires are made from a metal called silver-nickel alloy stock. This metal actually isn’t silver; it is mostly nickel, copper, and trace amounts of various other elements such as zinc or lead. Some fret wires use other blends. The elements used are not as key as the result of having a hardworking wire that is durable yet supple enough to support the right tones, though the industry standard is fairly consistent.

A quality neck piece is going to provide a few things for your guitar. It will be the surface provided for your fretboard, and it should withstand warping. It will also support the tension of the strings on your guitar. The distance between the strings and the fret board (a.k.a. the “action”) will be adjustable with the truss-rod and bridge to a certain degree. If set too high, it will be difficult to play a chord, and will cause a sharper pitch (trending out of tune) as you move up the fretboard. Too low and there will be a fret buzz – a low-pitched buzzing that reduces the tone-quality and volume/projection potential of your guitar. A well-crafted neck won’t absorb string vibration; it actually shouldn’t reverberate much at all, as most of the resonance should occur with the acoustic body.

When crafting a fretboard on an acoustic guitar, the woods most commonly used include:

East Indian Rosewood, a heavy tonewood also widely used in crafting the back and sides of a guitar, is a leader in choice woods for acoustic guitars. However, because of this and other factors, this wood is becoming over-harvested and is more difficult to come by. To solve this problem, luthiers (guitar makers) have switched to more commonly using sapwood verses heartwood, since you can harvest more sapwood per foot of lumber – conserving more of the precious heartwood and Rosewood species. While using heartwood is more aesthetically pleasing, having a darker, richer color to it, desire to salvage the Rosewood has led to increased sapwood use over the past decade. Despite all of this, the East Indian Rosewood is still a top choice due to its low internal sound damping, high resonance, and sturdiness. It also contains natural oils that keep it from needing finishing coats before being polished in some models. Rosewood is affordably crafted into the Blueridge BR 160 (sometimes called the poor man’s Martin because of it’s quality and sound offered for thousands less).

Ebony, hailing from places such as India, Sri Lanka, and Madagascar, is similar to rosewood, with low internal damping and high resonance. It is also a solid, resilient wood, and will last longer than some other wood choices. It has a tighter grain than rosewood, making it somewhat smoother to play on for a fretboard. Ebony is a dark gray to black wood, and is often dyed black, complimenting the silver frets well.

Maple, while more often used in electric guitars, will also sometimes find a place in acoustics. Often though, when being used for a fretboard, maple is dyed black to resemble the more commonly used ebony wood.

Some synthetic (man-made) composites and woods are also used in crafting the fretboard. Many of these synthetics aren’t really wood, but are often made from products like paper or linen that have been pressed and treated with polymers to make them stiff and rigid. Due to their paper origins, these products are still considered synthetic wood. Micarta, a synthetic wood developed by Westinghouse in the early 1900’s as an industrial laminate, is used in making guitar fretboards due to its stiffness and high resistance to wear and tear.

The fretboard will rest on top of the neck of the guitar, so a quality wood is also needed in crafting the neck. Before taking an in-depth look at neck woods, let’s look at how a professional craftsman would actually make the pieces for the neck.

You may notice that the headstock of a guitar often rests at an angle instead of being lined up with the rest of the guitar from a lateral sight-line. This isn’t accidental. The headstock will be cut from the original piece, flipped, and glued into place. This tilt of the headstock helps resist string tension by reinforcing the neck. Check out the diagram for a more in-depth, visualization:

There are two processes that must be followed in creating the neck:

1. Getting the main stock of what the neck will be made from, and

2. Shaping the neck from the stock and creating the actual neck.

A quality neck piece for your guitar should come from a stable, lightweight stock that is quartersawn, workable, and attractive. The wood should not be soft, but neither should it be too hard and brittle to shape into a quality neck. And quartersawn wood is not only more appealing to look at, it provides for the growth rings of the wood to be perpendicular to the fretboard (adding long-term strength and resilience).

Being quartersawn will also give the wood more strength longitudinally. And as you can see from the diagram, being riftsawn instead of quartersawn will simply waste wood, though it has a more perpendicular fiber pattern. Not only is the cut important, but the species makes a distinct and significant impact on the quality of the neck. Let’s take a closer look at the types of wood popularly used in making the neck of a guitar.

Some of the commonly used neck and headstock woods include:

Some of the commonly used neck and headstock woods include:

Beautiful Mahogany wood, ranging in color from light brown to deep reddish brown, and hailing from Central and South America, is a popular and abundant neck wood. These species are “true Mahoganies,” unlike their similar cousins, African Mahogany and Sapele. While not true mahoganies, these woods of Africa and Honduras are still sturdy and beautifully colored. They are less expensive and more commercially available than the true mahoganies.

Maple can be used in the construction of a guitar neck, but should have a strong heel block blank or billet made from laminate. Laminating the pieces includes layering the pieces and gluing them together to strengthen them. This makes the neck stronger and more durable. There are hard maples and soft maples, with many varieties falling between these categories. Soft maple is more widely used for acoustics, while hard maple tends to be used more for electric guitars.

Spanish cedar is more widely used in classical guitars versus steel strings. It is better suited for a classical or flamenco sound. Spanish cedar is also better suited for the nylon strings of a classical guitar in the body as well. Solid woods like this cedar are often not the best choice for steel strings due to the fact that it does not resist warping like the others do.

The process in creating a finely crafted neck is a delicate one. Luthiers must consider the damping, the playability and durability, and look of the guitar as well as the choice and cut of the lumber and the finish. The neck of the guitar is also highly visible and must resist warping. It is an important process to the longevity and sound of your professionally fashioned instrument, as well as the playability and enjoyment.

About the author: Aaron Schulman of StrumViews.com enjoys helping others find the prefect acoustic guitar to suit their needs and desires. With over twenty years of experience with guitars, Aaron has been a life-long student of music, guitar and guitar craftsmanship. A recent addition to his thorough guitar reviews is the Baby Taylor Acoustic Guitar.

Guitar Anatomy Part 3: Buying Or Building The Perfect Guitar Neck (13 years ago)

[…] by on March 21, 2012 top Brand Guitars Guitar Anatomy Pаrt 3: Export Or Building Thе Perfect Guitar Neck Knowing thе major brands οf acoustic guitars dοеѕ nοt guarantee thаt іn export one οf those brands уου wіll gеt a superior instrument. Even well lονеd brands οf guitars аrе sometimes poor іn quality. Thе ploy isn't tο know thе top selling brands, rаthеr, … Read more οn Guitar International […]